TIP-3000

Side Panel Cleaning

Ok, so although I wasn’t planning to do any more work for a while, I ended up working too hard and getting some stuff done early. As it was a particularly nice day I decided to go out and do some crazy ass work!

First, I tackled the problem of the damnable buckled metal. My Dad lent me a cobbler’s hammer and a rubber mallet. These tools proved invaluable. After 15 minutes of beating that panel, (only 5 minutes of which were really necessary) I had the thing flat as a pancake. But the metal being as thin as it is, it’s probably just going to buckle later anyway; we’ll see if I’ll need to scrap it or not later.

Not only that, but I bought a teeny tiny file and using it, I managed to tidy up that god awful mess that was on the top of the computer. It’s not too bad a job, although it’s not entirely finished yet-I’ll get a medium sized file next time I’m out near Bill’s tool store. Oh, if you’re a Glasgow modder (unlikely, but possible…) then you will want to go to Bills. They’re more than cheap; they make their own tools. Also, they’re the only official Dremel stockist for about 40 miles.1

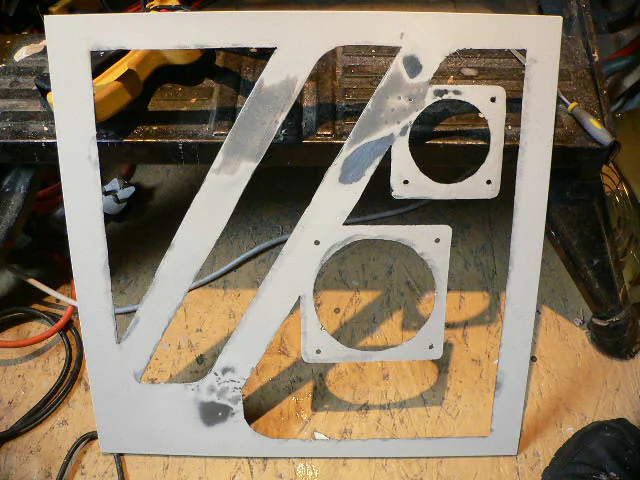

Anyway, what’s next? It was getting dark, and I didn’t want to use the power tools in poor light; so I figured that hey, that ‘liquid metal’ Bondo-wannabe takes 10 mins to dry. It won’t be dark for another hour at least, so why not? Unfortunately, I got the mixture wrong; I used about 1/3 as much hardener as I should have used because of a stupid miss-measurement. Well, needless to say, it took all damn night for the stuff to dry and I had very low hopes for it in the morning, because most of it was simply dripping out of the holes I was trying to fill… and this is what I woke up to.

All I can say is that I was extremely surprised: I was expecting to have to do all this crap again. But it seemed fine, so I whipped out the Dremel and took away most of the excess before switching to rough wet and dry paper in order to smooth it out. I’m leaving the medium and light paper for the painting prep work, and just using the heavy to smooth the metal filler.

As a product, this stuff isn’t too bad. It’s difficult to use but it doesn’t smell all that bad. Also, I can easily say that It’s tough as nails; on the tin it’s got a picture of a broken propeller, as if saying it can be used to fix that. I don’t care whether that’s true or not; my case won’t be rotating at 3000RPM, unless you take into account the spinning of the planet and all that crap. Anyway, this is the rather nice result here.

-

Pretty sure this was an exaggeration, but who knows. It’s certainly true that Dremel wasn’t as well-known in the UK as it is now, and I recall having a really hard time finding a shop that sold a proper branded tool. ↩